Breathe New Life into Plastic: The Power of Recycled BL3 Blow Moulding Grade Granules

In the world of recycled plastics, some heroes stand out with their versatility and performance. One such champion is Recycled Blow Moulding Grade (BL3) granules, ready to breathe new life into plastic products and minimize your environmental footprint.

What is BL3? A Versatile Warrior in the Plastics Arena

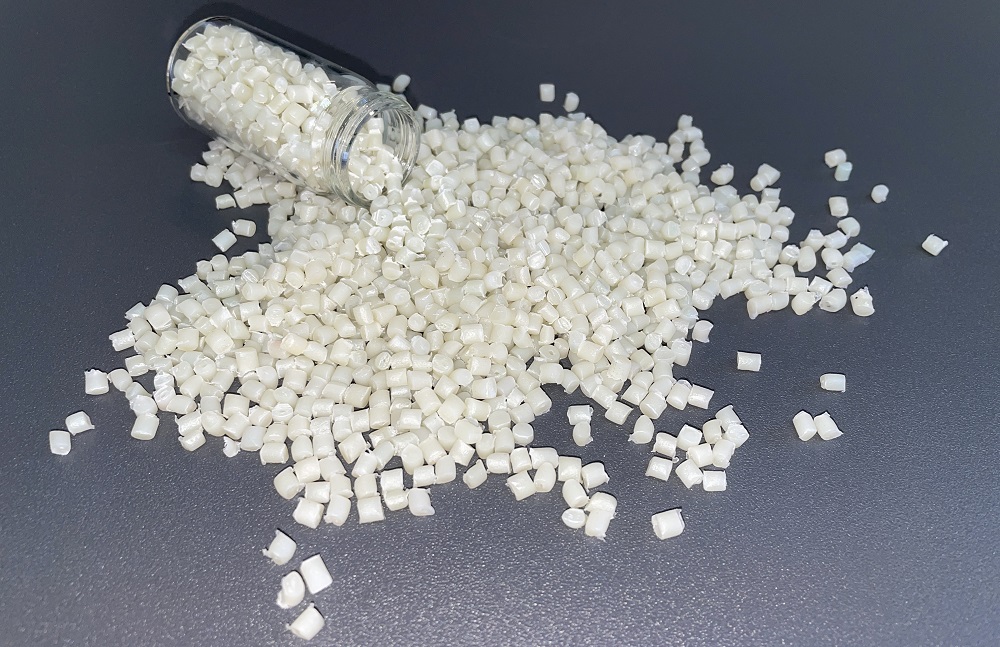

BL3 granules are high-density polyethylene (HDPE) pellets specifically designed for blow moulding, a process that shapes molten plastic into hollow objects using compressed air. Think sturdy bottles, durable containers, and even playful children’s toys – BL3 is the hidden hero behind their creation.

- Environmental Champion: Recycling plastic conserves precious resources and diverts waste from landfills. Every ton of recycled BL3 saves up to 1.7 barrels of oil, a true eco-warrior!

- Energy Efficiency Advocate: Compared to virgin plastic production, recycling BL3 demands significantly less energy, reducing your carbon footprint and contributing to a greener future.

- Cost-Conscious Ally: Recycled BL3 granules are often more cost-effective than their virgin counterparts, putting a smile on both your wallet and the planet.

- Performance Powerhouse: Don’t underestimate the “recycled” label. BL3 retains the exceptional strength, durability, and chemical resistance of virgin HDPE, ensuring unwavering performance in your finished products.

The journey of a plastic bottle to a recycled BL3 granule is an inspiring one:

- ollection: Used plastic products are diligently gathered from homes, businesses, and industrial facilities.

- Sorting: The plastic is meticulously sorted by type and color, ensuring each BL3 granule finds its perfect match.

- Cleaning: Contaminants are meticulously removed, leaving the plastic gleaming like polished gems.

- Shredding: The plastic is transformed into confetti-like pieces, ready for its grand metamorphosis.

- Melting: The shredded plastic undergoes a fiery transformation, melting into a molten stream of possibility.

- Pelletizing: The molten plastic is extruded into uniform BL3 granules, the building blocks of a sustainable future.

Challenges on the Horizon? We’ve Got This!

While recycled BL3 shines bright, a few challenges remain:

- Quality Assurance: The quality of recycled plastic can vary depending on the source material and recycling process. Partnering with a reputable manufacturer like yours ensures consistent excellence.

- Supply Chain Symphony: Ensuring a steady supply of high-quality recycled BL3 granules requires a well-orchestrated supply chain. Your expertise in navigating this landscape is invaluable.

- Cost Considerations: In some cases, recycled plastic may be slightly more expensive than virgin plastic. However, the long-term environmental and economic benefits far outweigh the initial investment.

To place an Order